Best Practices

Tier 4 Engine Technologies

Understanding How They Work, Plus Maintenance Tips

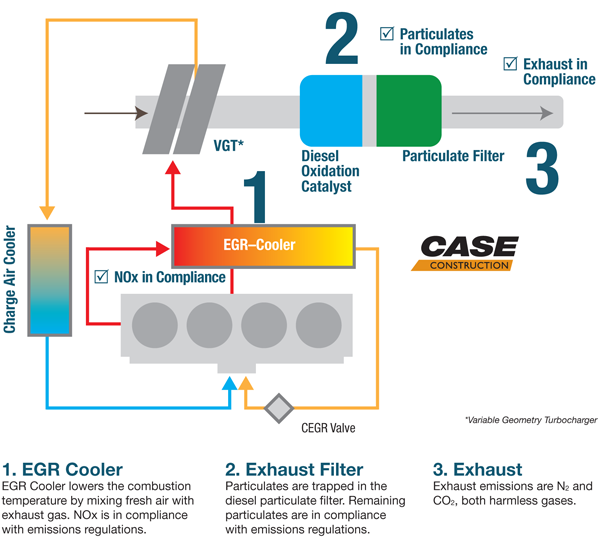

CEGR

Cooled Exhaust Gas Recirculation

In CASE backhoes, skid steeers, CTLs and C series excavators

Diesel Particulate Filter Tips

Performance

- The DPF works most efficiently at full load, gear up and idle back.

Maintenance

- The DPF is designed to last for a minimum of 3,000 - 3,500 hours.

- The filter is positioned for easy access on all machines to facilitate service, when required.

- The DPF is cleaned using a regeneration process, which occurs while the filter is on the machine.

- Low ash CJ-4 engine oil is required.

Operation

- Only use low sulfur fuel.

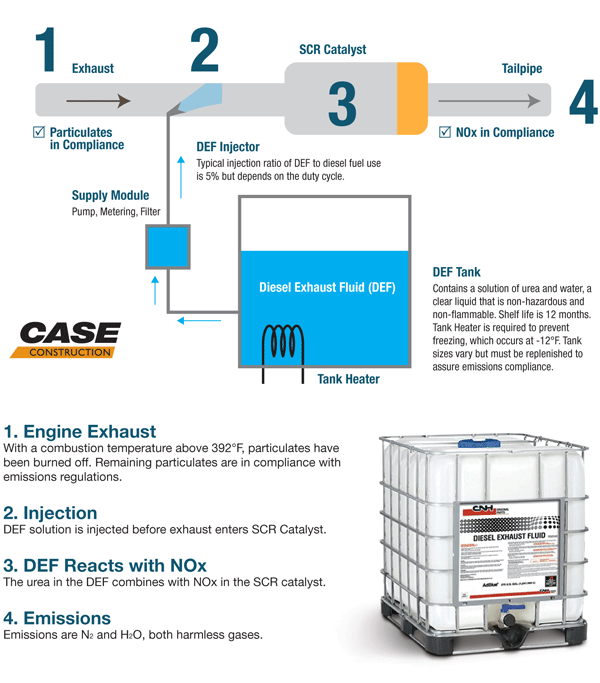

SCR

Selective Catalytics Reduction

In CASE dozers, backhoes, wheel loaders and D series excavators

Diesel Exhaust Fluid Tips

Maintenance

- Refilling the DEF tank can be incorporated into a regular maintenance or refueling routine.

- Always be proactive about checking DEF levels.

- Change supply module filters at required intervals.

- Low ash CJ-4 engine oil is not required but can be used.

Performance

- SCR system is separate from the main engine function and does not affect horsepower or torque.

- SCR technology is highly efficient and reduces fuel consumption.

Operation

- Each machine includes a DEF gauge and a warning signal when DEF level is low, similar to a fuel gauge.

- Only use low sulfur fuel.

Purchasing DEF

- DEF is available in four container sizes from Case: 2.5-gallon, 55-gallon drum, 275 or 330-gallon totes.